+49 (0) 5139 278641

FAQ

Brake discs are too thin to skim, why bother?

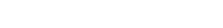

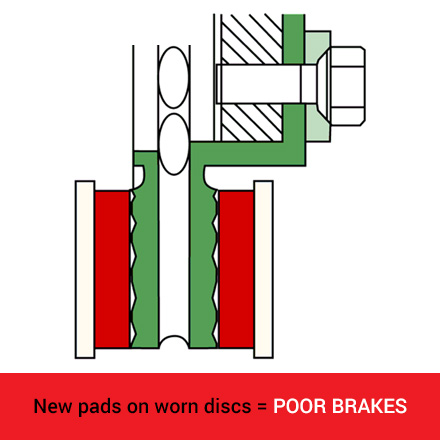

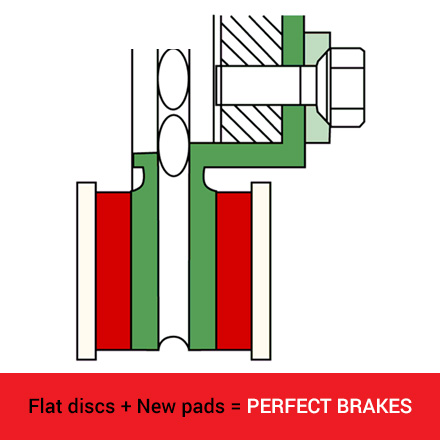

Front discs wear faster than rear discs as they do most of the braking. However all discs can be skimmed at least once and sometimes twice. Say a car needs new pads at 30,000miles, then skim the discs and fit new pads. 30,000miles later the discs might be too thin to skim again so sell the customer new discs. However measure the runout of new discs mounted on the hub and if its more than 0.02mm then charge the customer for trueing them in. Skimming does not make the disc any thinner, it just takes all of the disc to its narrowest point. If the disc was 26mm new and the narrowest part is now 25mm, but some bits are thicker than 25mm then the complete friction area of the disc will be machined to the 25mm thickness.

Can all my staff really use the machine?

All our brake lathes are super simple to use. We can train any member of your staff.

Can I machine drums?

Not all our machines will do drums. If this is important to you, let us know during the initial chat on the phone.

Can I machine flywheels?

Not all our machines will do flywheels. If this is important to you, let us know during the initial chat on the phone. Flywheels need grinding if they have carbon hard spots and we have a full range of grinders to suit all applications.

What are the real running costs?

25p electricity per disc, 25p cutting tips per disc. 10 minutes of your mechanics time and the machine cost of say £3 per day. Therefore if you did two discs per day and pay your mechanic £14/hr then it will cost you exactly £5.83 per pair of discs.

What about training my staff and certifying them?

Included in the price if full on site certification for your staff (max 3 people for 4 hours) Only only leave when your staff are experts at skimming brake discs

What happens if my skimming machine goes wrong, who fixes it?

Firstly they don’t go wrong that often, which is why we offer up to 3 years warranty. However if you have a problem we will fix it for you. We do not use sub-contractors. Normally most issues are resolved in 24hrs.